Exploring the cost savings from a stretch wrapping machine

Exploring the cost savings from a stretch wrapping machine

Blog Article

Let loose Efficiency in Your Stockroom Workflow With a Top Notch Stretch Covering Machine

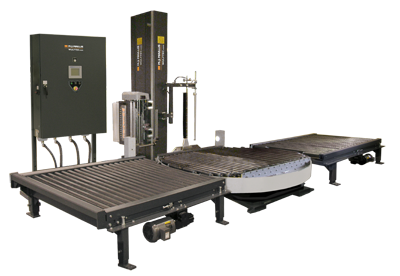

Productivity in storehouse operations rests on the efficiency of the product packaging process. The intro of a premium stretch covering equipment can be a game-changer, encouraging efficiency, decreased labor prices, and reduced human error. With the capacity to deal with different tons sizes and wrap numerous pallets per hour, these machines provide a compelling proposition for any business seeking to maximize its procedures. So, what makes these machines such an important property in warehousing? Let's discover further.

Comprehending the Function of Stretch Wrapping Machines in Storage Facility Workflow

In the vast world of warehouse procedures, the significance of stretch wrapping equipments can not be overemphasized. They offer a vital role in making certain that items are securely and securely packed for storage space or transportation. These makers use an extremely stretchable plastic film around things, securely wrapping them with each other in a means that hands-on covering simply can not match.

Effectiveness is another crucial advantage. Stretch covering devices can manage big volumes of products quickly, substantially quickening the packaging procedure. This can result in considerable time and price savings for companies. The consistent covering supplied by these machines can minimize the risk of tampering or burglary during transportation.

Key Functions of High-Quality Stretch Covering Machines

While there is a wide array of stretch covering equipments available in the marketplace, high-quality designs share particular key attributes that set them apart. These makers are normally durable, developed to endure substantial use without jeopardizing on performance. They use a high degree of automation, enabling easy and reliable wrapping of products.

High-quality stretch covering devices additionally include flexible settings, providing versatility to suit different packaging requirements. They can take care of different sizes and types of tons, making certain a secure cover each time. These machines are also renowned for their speed, with the ability of wrapping many pallets per hour, thus significantly increasing productivity.

One more trick attribute is their integrity and low maintenance need. Premium equipments are built to last, decreasing the regularity of break downs and the connected downtime. They operate with precision, ensuring consistent wrap tension, thereby reducing waste and improving the discussion of covered products.

The Impact of Stretch Wrapping Devices on Stockroom Effectiveness

The performance of a storage facility can be significantly improved with making use of high-grade stretch covering equipments - stretch wrapping machine. These devices streamline the packaging process, decreasing the hand-operated labor involved and subsequently, the chance for human error. This ensures a more consistent and dependable wrapping procedure, causing improved security of goods during transportation

Furthermore, stretch covering machines can handle a higher quantity of goods in a much shorter quantity of time contrasted to hand-operated read more covering. This increased performance can result in better usage of stockroom space as products can be packaged and moved more rapidly. The machines additionally use the adaptability to fit different shapes and sizes of goods, better improving functional performance.

Calculating the Return on Investment for a Stretch Covering Device

Taking into consideration the substantial advantages of stretch wrapping makers, it's important to understand the monetary ramifications of spending in such devices. The return on financial investment (ROI) calculation is a straightforward yet efficient device to examine the success of this investment. The ROI is calculated by contrasting the expense of the machine with the financial savings produced over my review here a details duration.

Businesses ought to additionally think about variables such as strategic positioning, functional efficiency, and scalability. In conclusion, computing the ROI offers a clear monetary perspective to lead the investment choice in stretch covering machines.

Real-world Study: Success Stories of Carrying Out Stretch Covering Machines

Attracting from the economic effects discussed in the previous area, it is just as enlightening to check out functional applications and success tales of business that have actually implemented stretch wrapping equipments in their procedures. One such example is a multinational electronic devices business which reported a 30% reduction in harmed products during transit after presenting stretch wrapping machines in their product packaging process.

Another success story entails a leading food and beverage firm. After executing a stretch wrapping maker, they witnessed a substantial enhancement in their product packaging rate, which in turn increased daily outputs and overall performance.

Finally, a prominent furniture manufacturer had the ability to reduce down their product packaging material prices by a staggering 40% after changing to stretch covering makers; they her comment is here concurrently decreased their carbon impact, making their operations a lot more sustainable. These real-world study show the remarkable returns and effectiveness gains that extend wrapping makers can bring to warehouse procedures.

Verdict

In final thought, purchasing a premium stretch wrapping machine can substantially enhance storage facility procedures. With its capability to minimize hands-on labor, reduce errors, and enhance space application, it substantially improves efficiency and earnings. The ROI, coupled with success stories from real-world applications, even more emphasizes the important role of stretch covering devices in attaining functional performance and organization success.

The introduction of a top notch stretch wrapping device can be a game-changer, appealing effectiveness, decreased labor costs, and reduced human mistake.In the vast world of stockroom operations, the value of stretch wrapping makers can not be overemphasized.The effectiveness of a warehouse can be considerably improved with the usage of top quality stretch wrapping makers.Additionally, stretch covering machines can handle a greater volume of items in a much shorter quantity of time compared to hand-operated covering.In final thought, spending in a top notch stretch covering maker can substantially enhance storage facility operations.

Report this page